Lamination Stampling Manufacturers and suppliers Bangalore In India

- Lamination Stamping is an exclusive cycle we created to give the advantages of both moderate and compound cover stamping, offering you lower tooling costs and speedier completion times. Intended for laminations up to 8 " in measurement, Hybrid Stamping can be a savvy answer for low-to-medium volume creation runs.

- Low Tooling Cost - our crossover tooling midpoints around 1/3 the expense of standard moderate tooling

- Unrivaled Accuracy - our half and half cycle is intended for severe resistances regularly expected in the engine lamination industry. We convey accuracy with regards to concentricity, evenness, and opening areas

- Speedy Turn-Around - our tooling is intended to be produced in weeks, not months.

- Stamping Press Capacities of 60-Ton as much as 700-Ton

- In-House Die Design and Engineering

- In-House Tooling Manufacturing and Assembly

- Stamping Press Capacities of 60-Ton as much as 700-Ton

- In-House Die Design and Engineering

- In-House Tooling Manufacturing and Assembly

- Scoring Press Capacity as much as 20-Tons

- Part Sizes from 4.5" to 48" in Diameter

- Slanted Slot Location and Skip Capabilities Available

Each business is unique. While acquiring your stamped lamination won't ever feel like you are basically a number on a monetary record. Our way to deal with addressing your organization's lamination stamping necessities is vastly different than the ordinary "off the rack" list stamping houses. Our stamping plan of action offers a really novel and new way to deal with the manner in which your organization is accustomed to purchasing stepped laminations.

We have an adaptable methodology while giving lamination stamping administrations. Our answers-centered way of thinking comes from the very rules that have empowered us to turn into the biggest Just-In-Time. Adaptability, customization, quality, speedy times required to circle back, and customized administration are establishment on which we have effectively constructed our business

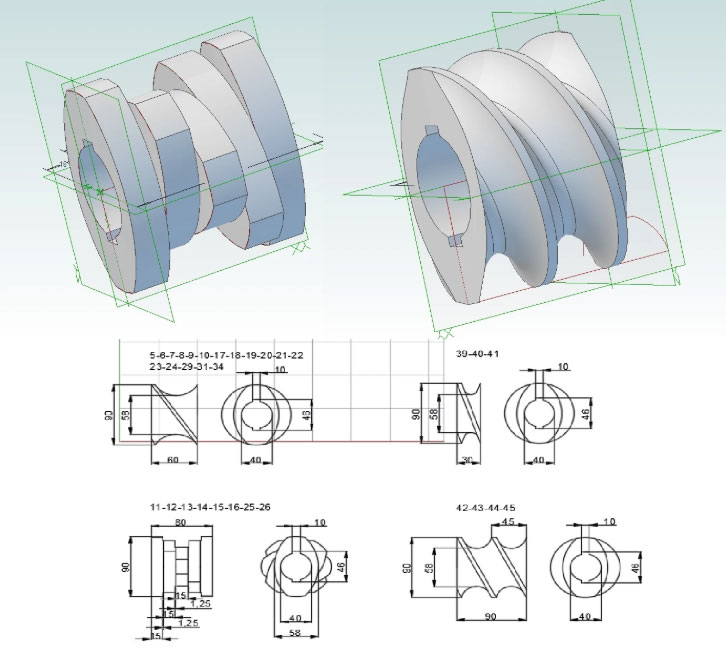

Lamination Stamping

Moderate Stamping produces a total part with no optional tasks. Utilized related to a programmed feed, the gradual stamping process delivers high amounts of parts in a short measure of time. However kicks the bucket regularly takes more time to fabricate and frequently cause higher assembling costs, Progressive stamping is great for complex parts requiring accuracy resilience.

Compound Stamping produces a total part in one station. While creation paces of compound stamping are generally slower, the expense of tooling is more affordable and the lead times to assemble the tooling is speedier. Compound Stamping is a decent arrangement when creation amounts are low and you require parts made with prevalent concentricity, levelness, and area.

Rotational Notching is a conservative answer for huge covers that disposes of the great tooling cost and long lead season of stamping. Parts can be created in weeks, not months with turning scoring. Our CNC Rotary Notching press uses a Servo Driven Indexer which is equipped for running rates up to 1,200 strokes each moment and creates profoundly exact parts with exact position ordering resistance. Intended for low-to-medium volume creation, Rotary Notching is an elective way to deal with delivering rotor and stator covers for a portion of the cost of traditional hard tooling.