Press Tools

Tooling is a manufacturing process used in the engineering industry and other industries such as automotive, manufacturing, mining, food, and science industries. However, putting efficient and functioning tooling in place helps enhance the quality of the product, production output capacity, the durability of the product. That’s why it’s so important for manufacturers to ensure they have functional press tools.

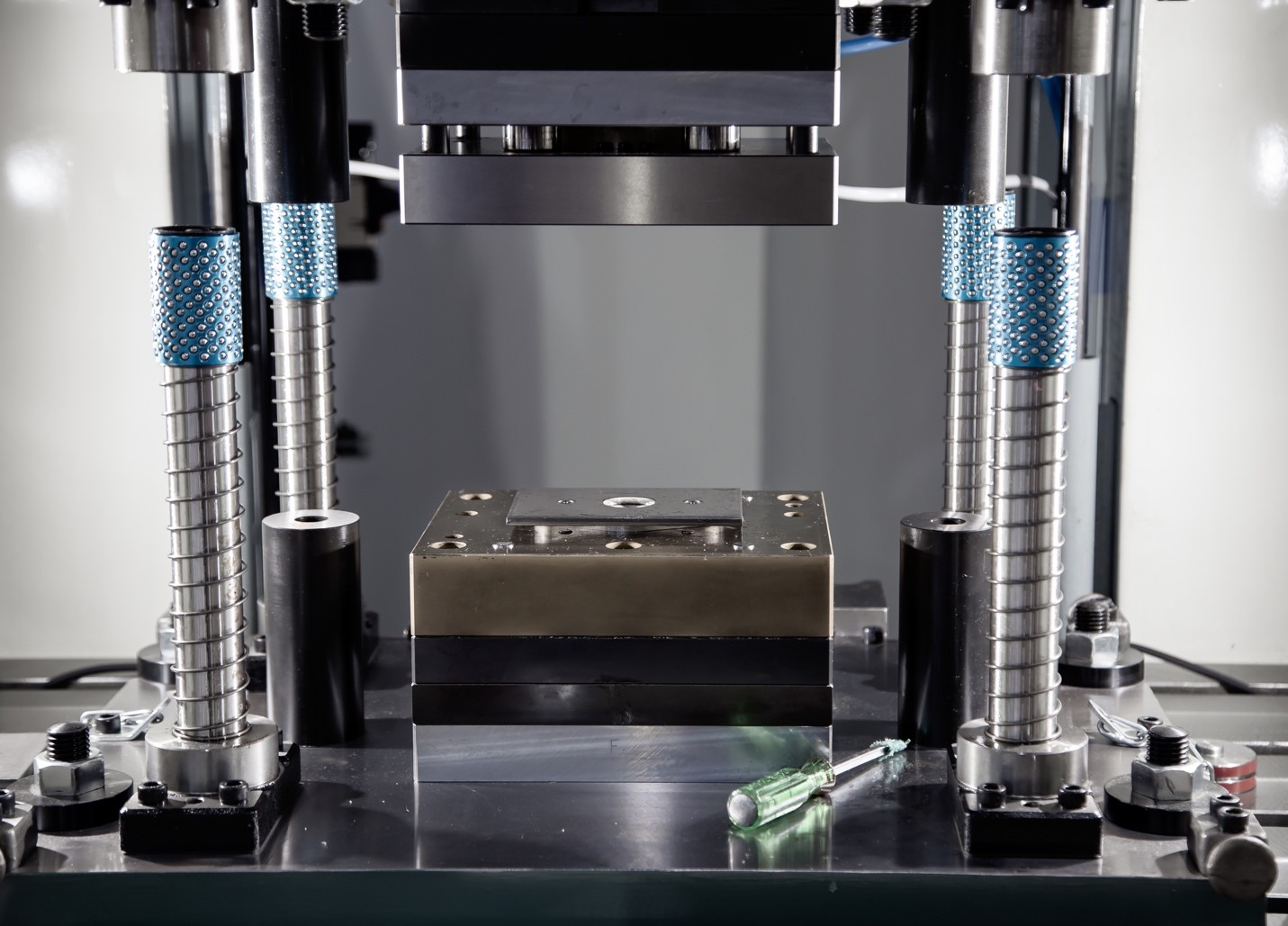

What are Press Tools?

Press tools are commonly used in hydraulic, pneumatic, and mechanical presses to produce components at high volumes. These press tools are used to change the shape of a work-piece. They are machines used to shape or cut metal into the desired form. There are various types of press used according to the requirements of the end product required. In a general term, press tools are categorized by the type of operation performed using the tools. Press tools vary essentially by operations from blanking to piercing, trimming, forging, forming and bending.

Are you in need of quality press tools?

Baiju Enterprises is a leading manufacturer of different types of press tools. Our service involves a professional tool evaluation and manufacturing of efficient and quality press tools that suit the manufacturer’s specifications.

Stamping Tools

Stamping tools, also known as press tools, are special tools that precisely cut and form metal sheets into any desired shape. These stamping tools are used in a process called stamping or pressing. Stamping is a complex process that includes many metal forming techniques. What actually is the metal stamping and the process of this complex yet widely used manufacturing technique? We will see all of this detail so that you can get the answers to all of your questions.

Progressive Die Stamping

As the name suggests, it is a metalworking method that serves as an alternative to the transfer press. Several processes such as bending, coining, punching, and several other steps are required to shape the sheet metal. That means With progressive tools, an entire series of machining steps can be carried out with a single press stroke.

Quality being our prime concern, we offer the highest quality Press Toolsfabricated in many designs and are engineered with high-grade raw materials. We manufacture them using the best quality raw components sourced from certified vendors to meet their requirements. At Baiju Enterprises, we produce high-quality, reliable, and cost-effective progressive tools. We have the proficiency and technological know-how to fabricate, quality test, and produce robust progressive tools that tackle a broad spectrum of production challenges.

Blanking Tools

Manufacturers use blanking to punch pieces in specific shapes from sheets or strips of raw material. Blanking is most often performed using hardened steel or carbide, which works on metals like aluminum, carbon steel, or stainless steel. Blanking machines range from simple punches and dies to sophisticated blanking machinery. This equipment can quickly be configured to end-product specifications. The process itself takes little time per part as it involves simply feeding the primary metal stock continuously into the blanking machine. Although the blanking process is a quick and cost-effective way to produce many identical pieces, manufacturers must take some considerations into account before embarking on an entire course of metal blanking. This is because some low-quality blanking tools may cause punched-out pieces to have burrs or cracks on the edges. However, by using high-quality tools, these drawbacks can be avoided, and they can be corrected by post-processing the blanks.

CAD Designing

Solutions to many engineering problems require a combination of organization, analysis, problem-solving principles, and a graphical representation of the problem. More so, objects in engineering are represented by a technical drawing that represents designs and specifications of the physical object and data relationships. Hence, engineering drawing entails using graphical symbols such as points, lines, curves, planes, and shapes. This is where CAD comes in. CAD (Computer-Aided Design) uses computer software to design and document a detailed product design process. CAD gives a detailed description of any component in a graphical form.

CAD-CAM Capability

Baiju Enterprises is a leading provider of AutoCAD design and drafting services comprising CAD with CAM (Computer Aided Manufacturing) services to a vast clientele worldwide. Our highly skilled and experienced designers, consultants, and CAD drafters can turn your ideas into reality from rapid prototyping and product development. We have the skills and technology needed to help you design files to meet your needs.

Deep Drawing and Forming Tools:

Deep drawing and forming tools are used in a metal stamping process called deep drawing. Deep drawing tools are used to stamp metal sheets into hollow vessels with different shapes and sizes. Commercial applications of deep drawing tools involve the shaping of metal sheets with complex geometries with straight sides and radii.

Notching Tools:

Notching tools are the tools and equipment that are used to punch the notches with a die in a metal sheet. The notching tools are used to manipulate the size and shape of metal tools, this process is called notching. The notching tools usually have two sharp blades, set at The tooling used in the notching process normally has only two blades, set at 90° angles to each other. Notching is a widely used technique used in the metal industry to bend and cut metal sheets.

We can help you to fully exploit this progress tooling technology design and manufacture a progressive machine that is suitable for your production. We ensure a proper inspection and testing of our equipment for accuracy and efficiency. Our reputation as one of the highest quality manufacturers of press tools in India has been earned by adhering to a policy of not compromising quality. We have a quality management system in place which was designed to be ISO compliant.

Why many companies prefer our Stamping tools?

Cost-Effectiveness:

One of the best benefits that most industries look forward to is the cost benefits they can experience from any advanced tool. The low-cost production of complex products in the companies that choose us is attributable to our progressive tools. Our top-notch progressive tools help businesses save a lot of money that would otherwise spend on repeated processes.

Low Scrap Material:

A lot of scrap material can cause a significant impact on the finances of any company. However, the precision and accuracy of our progressive tools make the best use of the metal, and it helps to reduce the overall scrap material while saving money.

Swift Production:

One of the critical elements is the continuous feed of the material; users can produce more parts in more frequency. Companies looking for high volume production benefit greatly from the kind of quantity they can get from our progressive tools.

Reduced Material Handling:

Material handling has a severe effect on the quality and finishing of the finished component. However, with the progressive tools from Baiju Enterprises, the process is simple, and there is reduced material handling. This ensures perfect finishing and on-time delivery and reduces the chances of human error during the overall project cycle.

Quick & Easy Setup:

Compared to tools from other manufacturers, our progressive tools are faster and easier to set up, therefore helps to save on the required time for the overall project.

Quality being our prime concern, we offer the highest quality Press Toolsfabricated in many designs and are engineered with high-grade raw materials. We manufacture them using the best quality raw components sourced from certified vendors to meet their requirements. At Baiju Enterprises, we produce high-quality, reliable, and cost-effective progressive tools. We have the proficiency and technological know-how to fabricate, quality test, and produce robust progressive tools that tackle a broad spectrum of production challenges.